The Importance of Manuals in a Time of Automation

The Importance of Manuals in a Time of Automation

The suddenness of the COVID-19 pandemic caused an unanticipated pause for companies around the world. Once the initial shock and shutdowns ended, company owners and managers scrambled for ways to stay productive. A new emphasis was placed on automation as a way to operate safely and continuously.

Using automation, manufacturers are able to leverage their human workforce in other productive ways, exert better control over their products, and quickly track down problems. And to keep everything running properly—automation requires documentation. ProWrite can create the right manual, from installation to operation and maintenance, for automated systems.

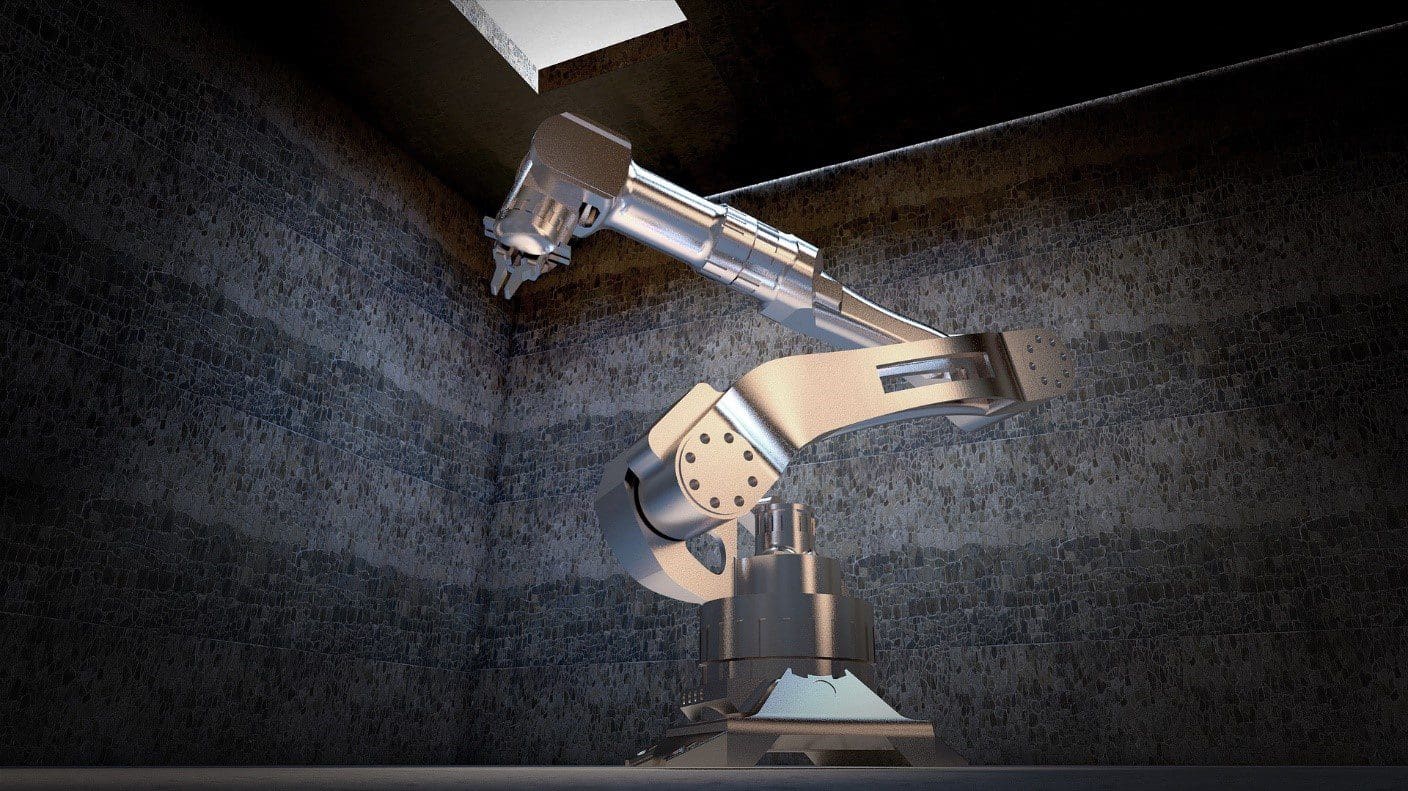

Automation is a fixed, programmable, or flexible system of manufacturing that uses robotics in place of people. Automation itself is nothing new; manufacturers have used robots to perform rote or dangerous tasks for decades. However, because of the coronavirus outbreak, owners and managers have looked to expand the use of robotics to reduce the number of people needed in factory settings to comply with social-distancing regulations and stay-at-home orders.

According to an article in Financial Times, “The pandemic is driving a shift in companies’ use of technology, both official statistics and business surveys suggest, making the automation and digitalisation industry one of the few winners from this year’s economic turbulence.â€

Elisabeth Reynolds, executive director of the Massachusetts Institute of Technology’s task force on the work of the future, said in the article that the spread of the virus “has accelerated the use of robotics and other technologies to take on tasks that are more fraught during the pandemic. It is fair to assume that some firms have learn[ed] how to maintain their productivity with fewer workers and they will not unlearn what they have learn[ed].â€

Although Reynolds’ prediction does not bode well for recouping those jobs, even after things go back to “normal,†it does shed light on the vital importance of instruction manuals more than ever. When a process is automated, the same number of people are no longer needed to complete the task. Those who remain will need a guide on how to keep the production process flowing without relying on the tribal knowledge of those they used to work beside

In 2018, Arnie Gordon, president of Arlyn Scales, wrote in an article for Forbes that artificial intelligence “is going to make automation more widespread and even more reliable.†Says Gordon, “This will make it possible for operations to become 100% automated at a given location with regular remote check-ins from a central hub.â€

Then came 2020, and the trend Gordon wrote about was accelerated. According to a report published in October 2020 in Switzerland by the World Economic Forum (WEF), “Automation, in tandem with the COVID-19 recession, is creating a ‘double disruption’ scenario for workers.†The WEF report reveals that a shift in the division of labor between humans and machines could displace an estimated 85 million jobs by 2025.

However, despite the potential for job loss, automation brings many positive possibilities. An article published in the January 2021 issue of Electric Motor Engineering explains how an Italian company that designs and manufactures plants to automate the mounting systems for electric motors is using automation to control and trace a product as it moves through its machinery.

Through automation, Cosberg is able to “integrate all available technologies to carry out tests, measurements and controls into the plants,†the article describes. The company’s owners and managers believe this level of automation allows them to ensure every product assembled on its machinery meets all industry specifications, while documenting the production information of each piece for troubleshooting or evaluation.

Alpha Technologies is a US-based, rubber and polymer rheology testing company. Alpha operates in plants around the globe, and the owners and managers are increasing their level of automation solutions in response to workforce reductions due to virus restrictions. In the process, like Cosberg, Alpha is finding ways to use automation to align processes and minimize the time it takes to solve any problems that arise.

For companies that are automating, once the system is in place, one person, or a smaller team of people, are charged with maintaining it, which increases the need for operational and maintenance manuals for those systems. Until robots can independently repair and maintain other robots, someone will need to know how to keep them functioning properly in efficient ways that minimize disruption to the manufacturing process.

ProWrite’s clients range in their level of automation, from those who have used it for a long time to those who are expanding its use due to the pandemic. Whether you are updating or introducing an automated system into your production line, our technical writers have experience building the manuals that can help that automation run smoothly no matter what else the future may bring.

Posted in Blog